-

CIPAX

SPECIALIST IN ROTATIONAL MOULDING

The manufacturing process at Cipax is characterised by cost-effectiveness for small-scale production runs due to low tool costs and flexible production. The flexibility in product design facilitates the manufacture of complex items. The materials used are fully recyclable. For reduced carbon footprint, production in recycled plastics and materials with bio-content is offered. The service portfolio includes everything from design and toolmaking to production and post-processing. Examples of customer-specific products include various tanks, pipes and casings with considerable breadth in respect of working temperature and good chemical resistance. Cipax also works with proprietary products such as industrial containers and tanks that can be buried. Most deliveries are made to leading companies in Northern Europe within sectors such as infrastructure, agriculture, cleantech, automotive and leisure.

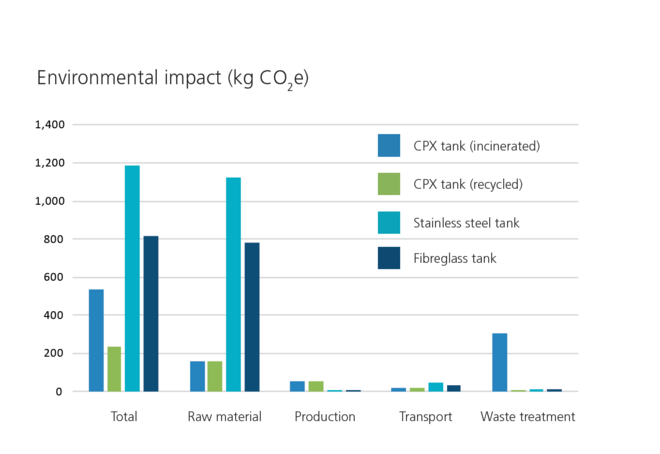

POLYETHYLENE – A GOOD ENVIRONMENTAL CHOICE

Helping to reduce the environmental footprint is important for Cipax. All types of production have an impact on the environment, so anything that helps to reduce this impact will generate positive effects for our shared environment.

Read more-

Cipax AB

Stinsvägen 11

SE-763 93 Skebobruk

SwedenPhone +46 (0)175 252 00

Email info@cipax.com

Website https://cipax.com/se -

Cipax Eesti AS

Nurme 5

EE-90801 Taebla

EstoniaPhone +372 472 44 30

Email estonia@cipax.com

Website https://cipax.com/ee -

Cipax Nederland B.V.

Jutestraat 22

NL-7461 TR Rijssen

The NetherlandsPhone +31 (0)548 515 172

Email info.nl@cipax.com

Website https://cipax.com/nl

-

Cipax Danmark ApS (formerly DRP)

Kalvehave Havnevej 3

DK-4771 Kalvehave

DenmarkPhone +45 55 38 01 02

Email info.dk@cipax.com

Website https://cipax.com/dk -

Cipax Norge AS

Holtermoen 12

NO-1940 Bjørkelangen

NorwayPhone +47 63 85 30 00

Email bjorkelangen@cipax.com

Website https://cipax.com/no -

Cipax Oy

Martinkyläntie 67

FI-01720 Vantaa

FinlandPhone +358 (0)9 727 60 06

Email info@cipax.com

Website https://cipax.com/fi