NEW TECHNOLOGY MAKING THE WORLD SMALLER

Jorgensen Engineering installs complete production facilities for the international food industry all over the world. The facilities’ capacity and efficiency are ranked among the very best in the sector, contributing to safe, reliable production for customers. “At Jorgensen, we know how important it is for the customer’s facility to be able to produce 24/7, all year round, and through new technology we are effectively minimising the risk of costly operational stoppages. With the aid of AR technology, our experts can now rapidly be ‘on site’ with the customer,” says Kenneth Bo Madsen, CEO of Jorgensen.

-

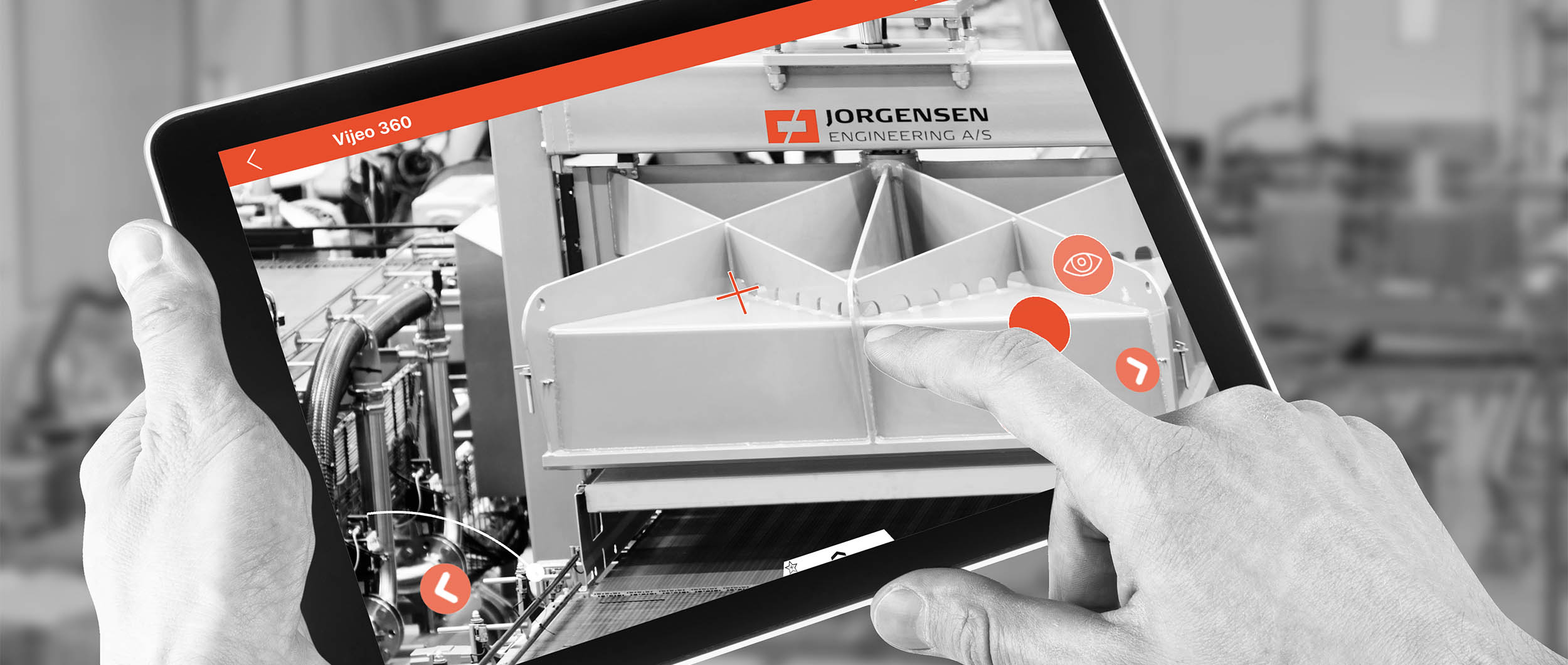

The AR technology means that the customer’s operator can easily get in direct contact with Jorgensen’s experts in Denmark, in real time. Using special AR glasses, Jorgensen’s employees can see exactly what the person on the site is seeing, which makes the work considerably easier. These glasses also provide the customer with information about the efficiency of the facility and any maintenance requirements, as well as access to manuals. “You could say that our AR solutions reduce the geographic distance, and when you have customers all over the world, like we do, this entails major benefits for both

-

them and us. We can now provide effective support in real time, no matter where in the world our customers are located,” says Kenneth, who also emphasises the significant environmental benefits due to the reduction in air travel. VR technology has also produced substantial benefits for Jorgensen’s customers. Large amounts of data can be analysed much more quickly than was possible just a few years ago, which is creating increased efficiency and customer benefit. “When we are designing large-scale facilities for our customers, we can present

-

them in a VR environment in advance. This allows the customer to get a feel for what the system will look like before it is produced and installed,” says Kenneth. All in all, this technology means that the customer’s investment is optimised, the installation time is minimised and any faults can be rectified before the facility is put into production. To all intents and purposes, the customer can test new products in a virtual environment before they are produced in a real one. This increases food safety, delivery reliability and, not least, the security of Jorgensen’s customers.